Reverse Engineering

Reverse engineering involves analysing an existing object, breaking it down into its core components, and measuring critical dimensions to understand its function and methodology, enabling improved design specifications.

Why customer need the reverse engineering service?

- When the customer has the physical product but not have the digital data like 3D and 2d manufacturing drawing of the product.

- When customer have the partial data of the product.

- When customer have only the 2D drawings and he want to modified the product.

- When customer have the physical product and he want to understand and know the critical dimensions of the product.

Who needs Reverse Engineering Services?

Engineering

Industries

Pharma Machinery

Industries

Fabrication

Industries

Road Construction

Machine Manufacturing

Industries

Hydraulic Equipment

Manufacturing

Industries

Industry Served By Us

Mechanical

Engineering

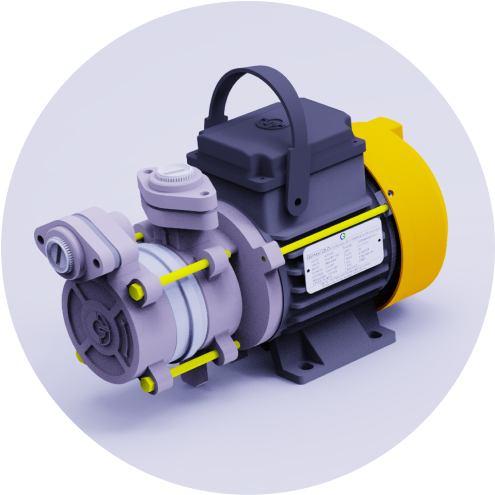

- Pump

- Hydraulic system & Hydraulic Cylinder

- Manifold Block Design

- Crusher, Screen, Conveyor, Vibro Feeder, Grizzly Feeder, Bitumen Tank & Diesel Tank

- Piping For Hydraulic System

- Road Construction Equipment

- Fixture Design

Structure

Design

- Storage Silo for Different Application

- Fabrication Structure

- Container Design

Pharmaceutical

Industry

- Conveyor

- Tablet Filling Machine

- Labeling Machine

- Packing Machine

Our Process

1.

To understand the physical product

2.

Data collection from the product

3.

Prepare the 3D model of the product

4.

Validate with the customer

5.

Incorporate the customer feedback

6.

Final submissions

FAQs

What is reverse engineering?

Reverse engineering is the process of analysing an existing object to understand how it works and was made and modified as per customer requirement.

For which type of product we can do the reverse engineering?

For mechanical components and machine we are capable to do the reverse engineering.

What will be the deliverables of the reversing engineering?

The deliverable of the reverse engineering is the actuate digital data like 3D and 2D of the product.

Can the reverse engineering resolve the error?

Reverse engineering can be as powerful tool to resolve the error with the help of the different software and technique.

How reverse engineering can be useful?

Reverse engineering can be useful for many purposes, including: improving functionality, enhancing performance, solving problems, learning from competitors, and creating new innovations.

Related Services

3D modeling is a tool that can help engineers at every stage of a project, including designing, conception, and presenting

When it comes to converting the 3D design into real components 2D drawings are the best communication tool that allows mechanical engineers to convey problems, solutions